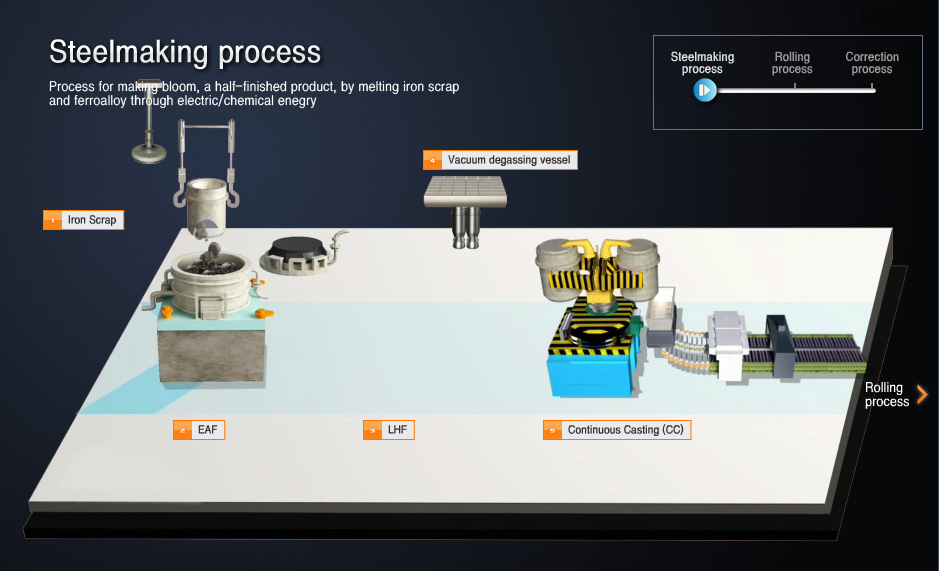

Special steel material purposes

- Engine

- Drive

- Axle

Production capacity

- Steel

- 310 million tons

- Product

- 280 million tons

영상이 자동 재생중이니 정지하시려면 다음의 버튼을 클릭하시기 바랍니다. Play/Stop

- 현재위치

- Products

- Process Simulation

-

- 01Iron scrap

- Main material for electric furnace steel manufacture

Scrap metal discarded from the production or process and after the end of lifespan of finished steel products

-

- 02EAF (Electric Arc Furnace)

- Process of melting solid iron scrap into liquid metallic strain using electrical and chemical energy

- Electrical energy: thermal energy of Arc occurring between electrode and iron scrap

- Chemical energy: thermal energy occurring between oxygen and metal element

-

- 03LHF Ladle Heating Furnace

- Metallic stain produced in the electric furnace received in a vessel called ladle

- Rise in temperature using electric energy

- Adjust chemical elements through alloy metal insertion

- Process that reduces refinement through making optimum slag

-

- 04Vacuum degassing vessel

- Process of degassing hydrogen, nitrogen, oxygen and etc. in metallic stain by exposing finished clean metallic stain to low vacuum state under 0.8m bar lower than atmospheric pressure

- VD: Equipment that exposes ladle with metallic stain into a vacuum state by putting it in equipment in a tank form

- RH: Equipment that exposes metallic stain in ladle to a vacuum state by reverting it into a particular vessel

-

- 05CC Continuous Casting

- Equipment that produce bloom/billet continuously by infusing melted steel in a certain form of mold

- Clean steel and high alloy steel production through M-EMS/F-EMS and dynamic soft reduction equipment

-

- 01Walking Beam Furnace

- Process of heating blood produced by soft mold uniformly (at approximately 1200 degrees Celsius) to facilitate plastic deformation

Characteristics

- Chemical impurity decrease in the mold structure from spread caused by high-temperature heating

- During rolling, air bladder or porosity in the steel lump disappears and coarse grains refined

-

- 02Cogging Mill (Hot rolling mill)

- Plastic deformation process which desired shape and standard are formed by reversibly rolling the heated bloom with a pair of roll

Characteristics

- Destroys the big mold structure and improves the crystal structure of material to provide excellent mechanical and physical qualities

-

- 03Hot Scarfing

- Process of removing harmful defects (cracks, shells, superficially added substances) on the surface of material that does not extinguish in the course of heating and blooming

Characteristics

- Removing decarburized layer generated during the job of heating from the surface

- Applicable to high carbon steel and alloy steel that is incapable of cold scarfing

-

- 04Large-Bar Mill

- Process of halfway rolling and manufacturing the shape and standard of final product after hot rolling

Characteristics

- Production of RB105 to 250 products and manufacture the shape of halfway rolling

-

- 05Vertical-Horizontal Mill #1

- Rolling process for manufacturing the final shape and standard of product after hot rolling

Characteristics

- Production of RB75-1165.1, SQ83-160 products

-

- 06Vertical-Horizontal Mill #2

- Rolling process for manufacturing the final shape and standard of product after hot rolling

Characteristics

- Production of RB75-1165.1, SQ83-160 products

-

- 07Cooling Bed

- Inner quality improved and straightness secured by revolving and gradually cooling a rolled product

-

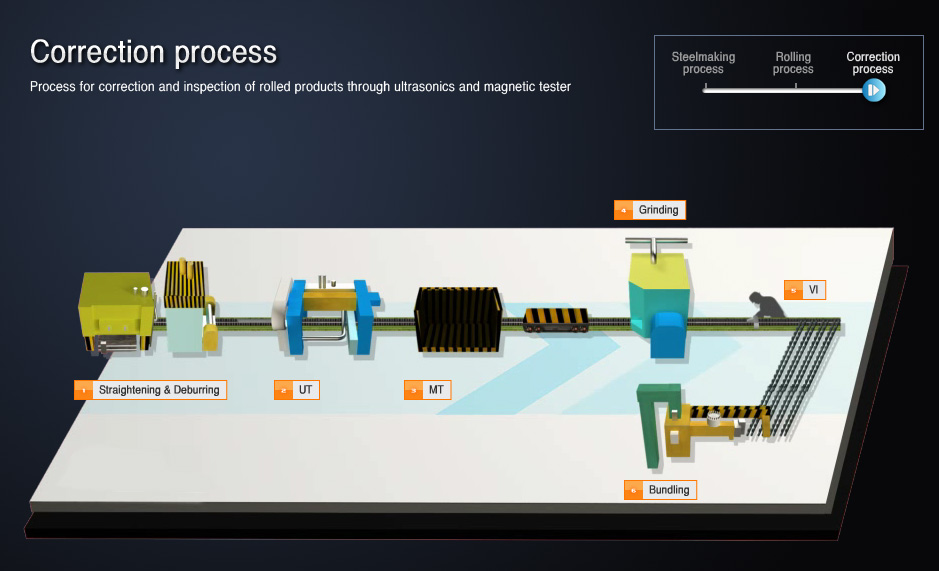

- 01Straightening&Deburring

- Straightening: equipment that secure straightness by passing a round bar through 2 rolls up and down

Deburring: equipment that removes the burr at both ends of product by fitting cutting tip with bite holder

-

- 02UT (Ultrasonic wheel probe)

- A type of NDP (non destructive testing), an equipment for discerning defects inside a product using ultrasonic waves

-

- 03MT (Magnetic particle testing unit)

- A type of NDP (non destructive testing) equipment that checks defects of the product surface by magnetizing and scattering fluorescent magnetic particles on the product

-

- 04Grinding M/C (Lapping tool)

- An equipment that removes the identified and marked surface defects via MT with grinding wheel

-

- 05VI (Testing with naked eyes)

- Final testing on the product (dimension, length, straightness, surface, etc.)

-

- 06Bundling (banding)

- An equipment for bundling products in certain units and weights